Company

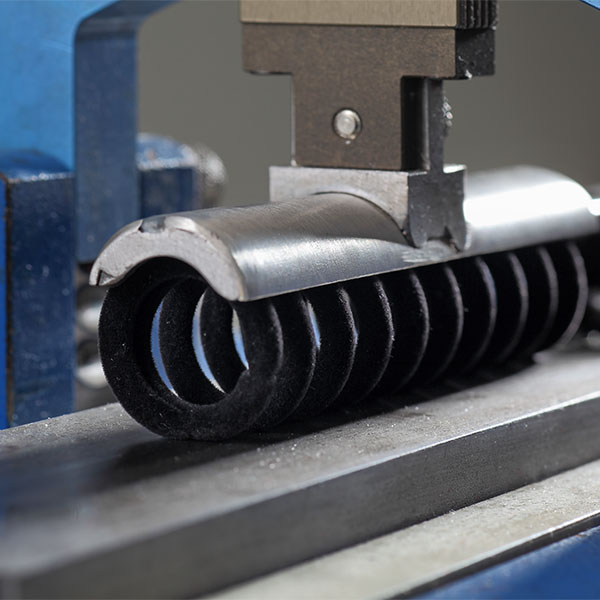

The stars on the world championship jersey of the German national team, interior covers of jewellery boxes, glasses cases or the glove compartment in a car have one thing in common: they are coated with flock. As a specialist in this sector, we – the PFT company with headquarters in Herscheid – use all traditional flocking techniques and thereby provide our customers with customised solutions. Countless objects from everyday life are refined, upgraded, protected and made more “hand-friendly” at our plant. Among these are car door seals and compartments in the interior as well as screw heads. Particularly in demand are springs, which we flock with a velvety soft yet extremely robust cover and which are used, for example, in boot lids for SUVs and many other vehicles which open and close automatically. This prevents annoying clicking noises.

Our company was founded at the end of 1993 to succeed the F.-J.-Rath Flock-Technik company with headquarters in the Plettenberg industrial park. We were able to transfer the concentrated know-how of this company into the new company and grow from 43 employees then to 80 employees now in just a short period of time. Since 2006, we have also been developing and constructing flocking machines and devices. This means we can react extremely quickly and productively to customer requests. Major customers in the automotive sector, manufacturers of household appliances and mid-sized companies in the furniture, packing and entertainment industries trust in the wealth of experience we have been able to gain in both industrial flocking and in design flocking.

Moreover, we are an active member in the “Flock Association of Europe”, whose main objectives are in accentuating the major advantages and special features of flocking technology. A second main focus of the association is to promote advancement and evaluation of all flocking techniques and standardisation as regards quality, safety and environmental compatibility.

Moreover, we are an active member in the “Flock Association of Europe”, whose main objectives are in accentuating the major advantages and special features of flocking technology. A second main focus of the association is to promote advancement and evaluation of all flocking techniques and standardisation as regards quality, safety and environmental compatibility.

History

-

1993

Founding year – formed from Rath Flock-Technik, located in Bannewerthstrasse, Plettenberg

Employees: 10 -

1997

Move into new production facilities, located in Ziegelstrasse, Plettenberg

Employees: 30 -

1998

Business expansion with a second factory section, large-scale production of rubber profiles

Employees: 40 -

1999

Changes to the proprietary relationships and in the general management

-

2000

Large-scale production of seat support elements

Employees: 45 -

2001

Business expansion with the 3rd factory section and office expansion

Employees: 65 -

2003

Certification in accordance with ISO 9001:2000

Employees: 75 -

2004

Assimilation into the WMS Flock-Technik Group

-

2006

Re-certification in accordance with ISO 9001:2000

-

2007

Move into more advanced production facilities at Reidemeisterstrasse 1-3, Herscheid

Employees: 75 -

2009

Bankruptcy of the WMS Flock-Technik Group. Withdrawal from the WMS Flock-Technik Group.

-

2010

New machine and method technology for fully automated flocking of torsion springs. New general management and new shareholders. Former managing employees now form the new general management team.

-

2011

Re-certification in accordance with ISO 9001: 2008 with validity until October of 2014

-

2012

The construction of the new production facilities with an additional 500 sqm of production space began in November. Starting in May of 2013, 5 new flocking lines will go into service here.

-

2013

Completion and commencement of production in the new Hall 2.

Employees: 48 -

2013

PFT Flock-Technik GmbH can look back at 20 successful years in the world of flocking. An experienced, long-standing team of personnel used to be a guarantee for continual, healthy growth.

Employees: 60 -

2014

Renewed certification in accordance with DIN ISO 9001:2008 valid until October of 2017

Employees: 80

Construction and building of a flocking line for compression springs up to a length of 1,450 mm.

Move into Hall 3 and commencement of production with the 2nd fully automated spring flocking line. Tension springs and compression springs are flocked here in a 3-shift system. -

2015

Construction and building commencement of an additional fully automated machine for flocking compression springs.

Employees: 80 -

2016

Initial operation of the 3rd fully automated flocking line for tension springs and compression springs.

Employees: 85

Renewed certification in accordance with ISO 9001:2008 -

2018

25 years PFT

-

2019

Commissioning of the 4th, fully automatic flocking line for tension and compression springs.

Start of construction of the 5th, fully automatic flocking line for tension and compression springs.

Construction and commissioning of a new, automated system for flocking tension or compression springs that are only partially and only externally flocked. -

2020

Foundation of SC PFT Flock-Technik S.R.L. in Romania.

Commissioning of the 5th, fully automatic flocking line for tension and compression springs. -

2021

Environmental management system certification ISO 14001.

Production

We have been refining industrial and brand-name articles with our modern and individually developed fleet of machines since 1993. Throughout, we use very diverse flocking materials which are optimally adapted to the surfaces to be flocked and to how the materials will be used in future. Among these are polyamides ranging in length from 0.3 – 10 mm, polyester ranging in length from 0.3 – 1.2 mm, viscose ranging in length from 0.3 – 6 mm and cotton ranging in length from 0.3 – 0.5 mm. Added to these are various titres and colours so that we have the right material available on location for virtually every intended use.

Quality

Flocking parts is, for the most part, an adhesive process which requires a very high degree of adhesive strength. Adhesive is applied to either the entire surface or part of the surface. The flock shoots into the surface perpendicularly in an electric field and is then fixed to the substrate securely after drying. With our innovative technology, we are able to guarantee that the adhesive adheres outstandingly to the substrate. In order to guarantee optimum adhesion, we also use the fluorination technique as a pre-treatment. One of many pre-treatment methods at PFT.

Certification

In our company, quality always comes first.

From the receipt of the goods to the complete production process through to the delivery to the customer, a range of different checking and measurement processes control the dimensional accuracy and evenness of the flocking. Appropriate records and test reports are also available to our customers upon request.

Since 2003, our company has been certified according to ISO 9001:2000.

We are currently certified according to DIN EN ISO 9001:2008