Fluorination

By treating it with fluoride, plastic becomes even more pliable which means it becomes even more versatile in its areas of application.

In order to attain optimum flocking results, we work with a two-chamber fluoride gas reactor. This means we are able to offer specially tailored solutions to our customers. With the offline technique, it is possible to fluorinate geometrically independent moulded parts made of diverse materials using their special parameters in a way that is both economical and gentle on the environment.

We are happy to offer this to you in connection with pattern fluorination so that you can also be convinced by the quality and suitability.

Advantages

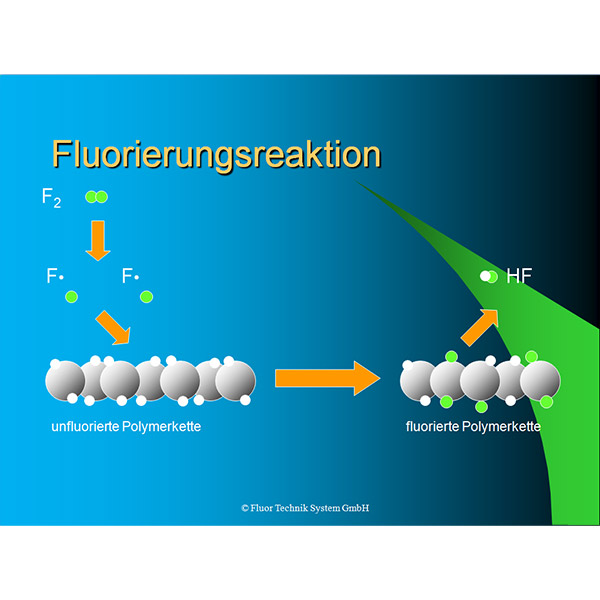

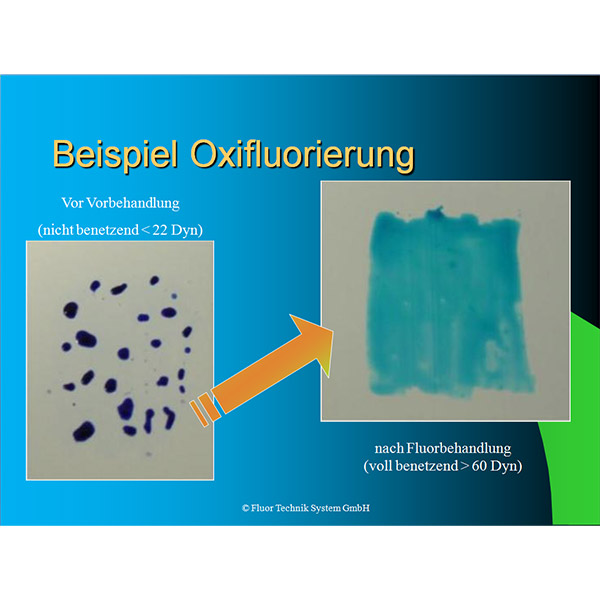

With the fluorination process, the custom positive characteristics of plastic are optimised. Non-polar becomes polar, non-adhesive becomes adhesive, hydrophobic becomes hydrophilic and non-wettable becomes wettable.

Nevertheless, all mechanical and thermal properties remain intact. Moreover, the plastic parts appreciate in value due to the fluorination.

A flocked part has a more attractive appearance, it doesn’t rattle, it protects the material, it feels more pleasant and it is easier to mount. Furthermore, flocked parts have a higher degree of storage stability, the complex 3D geometries are treated evenly and reproducibility is guaranteed.

Fluorination on commission

Our machine capacities also allow us to take on fluorination work on a commission basis.

Please enquire specifically for this service. We would be happy to provide you with an economic estimate.